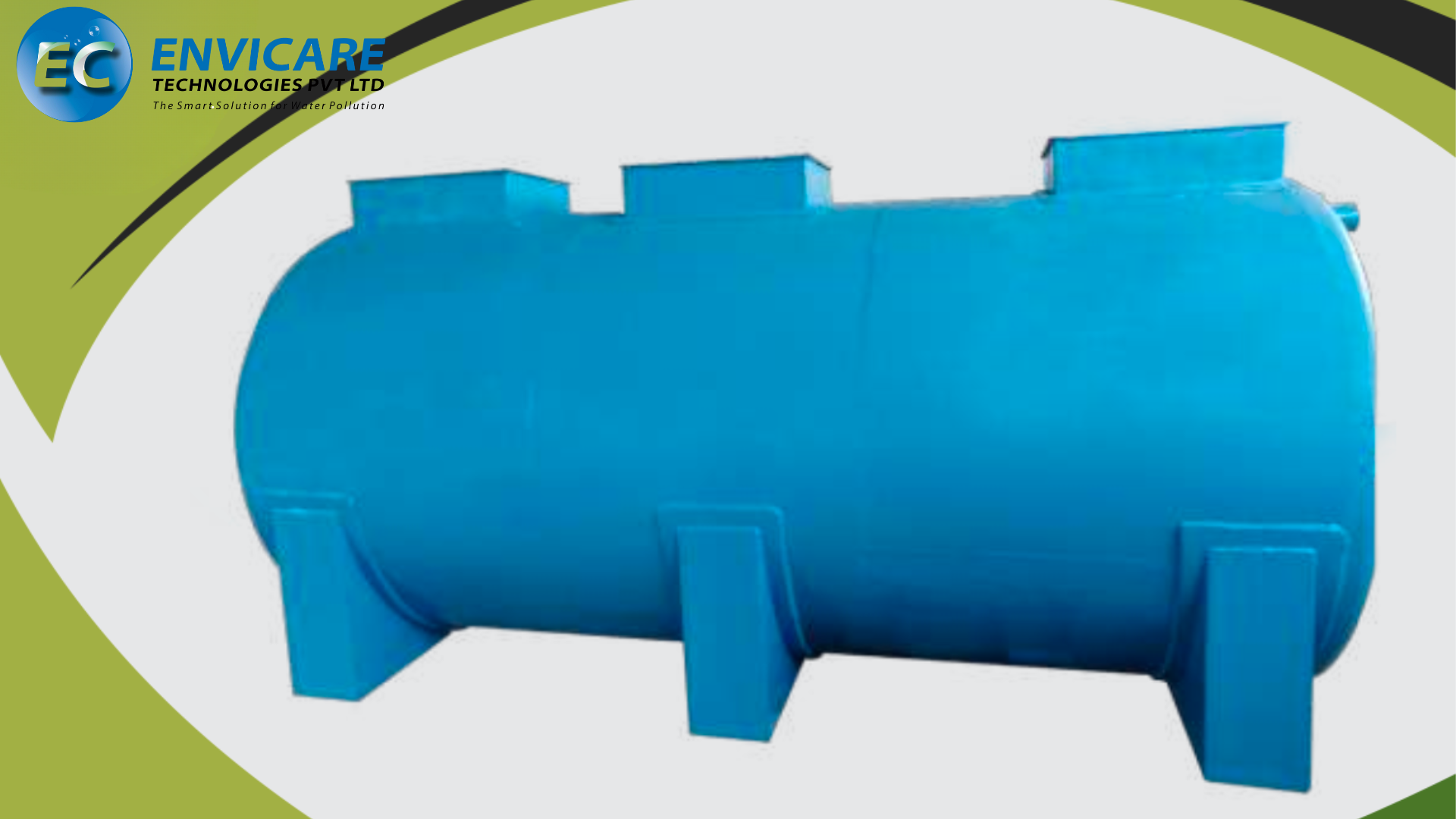

Containerised EcoBox ETP – Technical Highlights Capacities Available: 25 – 150 KLD (Customizable as per client requirement) Treatment Technologies: Physical, Chemical, Biological, Ultrafiltration (UF) 🚀 Key Features Compact & Aesthetic Design – Saves space and fits seamlessly into existing premises. Plug & Play System – Minimizes installation and commissioning time. Semi-Automatic Operation – Easy to manage with minimal supervision. Portable & Modular – Easy to dismantle, transport, and reinstall. Customized Solutions – Designed and manufactured to client specifications. Minimal Civil Work – Only requires a collection tank and container foundation. 🏭 Ideal for Industries Like: Chemical Pharmaceuticals Automobiles ✅ Benefits Reduced site work and faster project completion. Environmentally friendly with enhanced treatment performance. Built to meet stringent Pollution Control Board (PCB) norms. 🔧 Detailed Technical Specifications Operation Type: Semi-Automatic with easy control systems. Construction & Material: Process Tanks: Mild Steel (MS) with internal FRP coating for corrosion resistance. Piping: Corrosion-free UPVC piping for longevity and low maintenance. Foundation Requirement: Only basic civil work – collection tank and container base. Advanced Treatment Components: Automatic Chemical Dosing with online pH monitoring. Advanced Filtration Options: Integration with UF (Ultrafiltration) and RO (Reverse Osmosis) for Zero Liquid Discharge (ZLD), if required. Sludge Management: Provision for advanced sludge handling system (if opted). System Design Benefits: Compact layout with minimal footprint. Pre-fabricated containerized structure ensures fast deployment. Designed for high efficiency and durability in challenging industrial settings. Customization: Systems tailored for batch or continuous type operation based on effluent characteristics and client needs.

Send Message