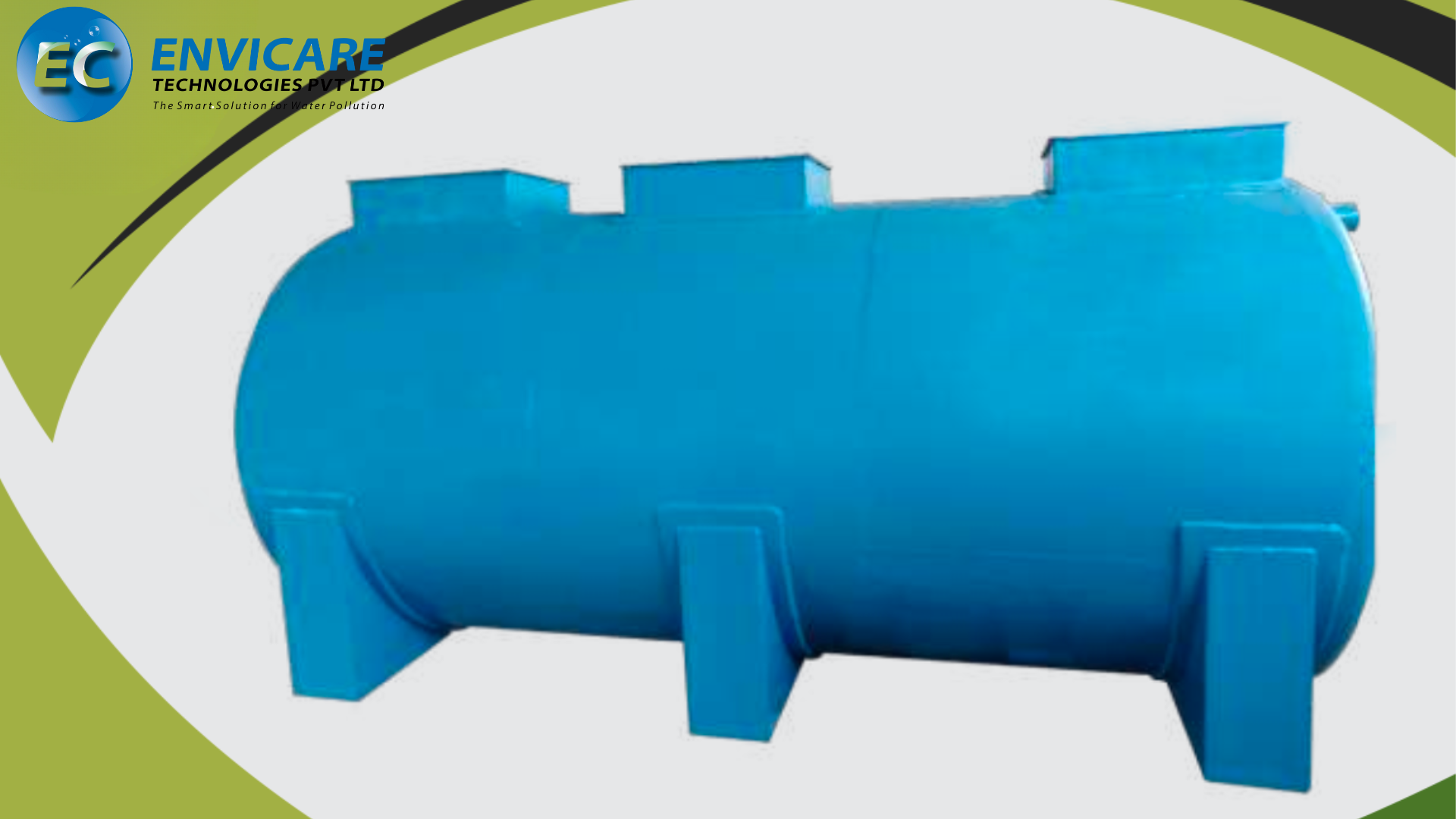

🏗️ Envicare’s EcoPack : Package-Type Prefabricated Sewage Treatment Plants (STP) ✅ Compact | Above-Ground | Efficient | Made-to-Order Envicare’s Package STP (Prefabricated Sewage Treatment Plant) is the ideal plug-and-play solution for medium-scale sewage treatment needs. Built using advanced biological treatment technologies like MBBR, SBR, SAFF, and MBR, this factory-assembled unit ensures quick installation, minimal civil work, and full PCB compliance with BOD < 10–30 mg/L. 📦 Product Snapshot Parameters Details Capacity Range 25 KLD to 250 KLD Technology Options MBR, MBBR, SAFF, SBR MOC of Tank MS-FRP Coated / MSEP Installation Type Completely above-ground (only civil work for sewage collection tank) Operation Semi-Automatic, Easy Monitoring Footprint Compact Design – Ideal for limited space Fabrication Fully Prefabricated at Factory – Standard & Customized Models Deployment Time Rapid Installation and Commissioning 🚀 Key Features ✅ Zero Heavy Civil Construction Required ✅ Factory Built & Tested ✅ Highly Portable – Easy to Relocate ✅ Fast Setup – Ready in Days ✅ Designed for Harsh Indian Conditions ✅ Trained Team for Erection & Commissioning ✅ Low Energy Consumption ✅ Aesthetic & Compact – No Visual Clutter 🧪 Performance Parameters 🧪 Performance Parameters Parameters Raw Sewage Treated Water (PCB Norms) pH 5.5–8.0 6.5–8.5 BOD (mg/L) 200–250 <10–30 COD (mg/L) 500–600 <50–100 TSS (mg/L) 150–200 <10–30 Oil & Grease <25 <5 🏭 Suitable For 🏘️ Housing Complexes 🏢 Commercial & IT Parks 🏭 Medium-Scale Industries 🏨 Hotels & Restaurants 🏗️ Labour Camps 🏥 Hospitals & Clinics 🔍 Key Features Prefabricated STP plant Package type sewage treatment plant Above ground STP system Compact sewage treatment unit MBBR based package STP Ready-to-install STP for industries Modular STP plant for residential complexes Plug and play STP system STP plant with MS-FRP coating Medium size sewage treatment solutions

Send Message